Designers use the software called Electronic Design Automation (EDA) to collaborate during designing. PCB design software offers the advantage of enabling electronic circuits to be created and visualized digitally, thereby saving cost otherwise incurred due to potential errors, failure, and repairs. Designing and fabricating PCBs requires PCB design software, which also reduce cost.

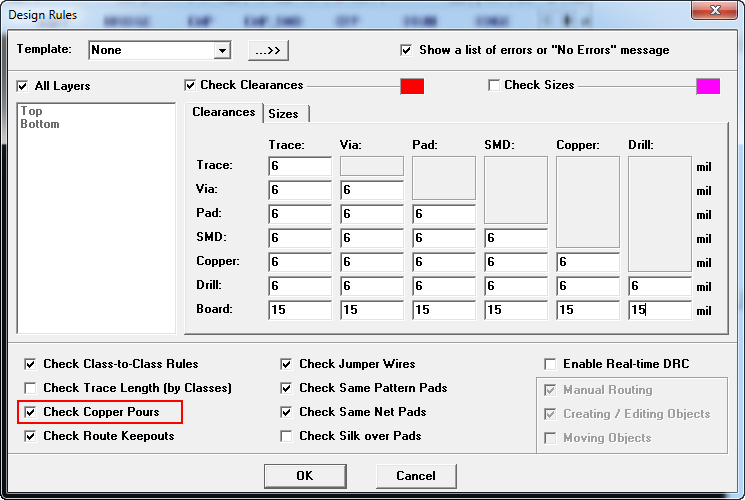

PCB design is a layout of the circuit of an electronic device and is vital in various electronic components such as transistors, resistors etc. PCB manufacturing is a costly procedure and PCB design software is also used to avoid circuit failure. The main function of PCB software is to construct, inspect, and test a designed circuit board before it can be printed physically on a polymer circuit board for use in the electronics sector. In order to find optimal models, engineers can easily select electronic components in a 3D setting or can change between several designs. Increasing need to minimize design errors of printed circuit boards is a key factor expected to continue to contribute to revenue growth of the market between 20.ĭesigners can develop PCB in shorter time by using PCB design software which comes with electrical templates and easy to use interfaces, which results in reduction of both production and marketing time. Market revenue growth is expected to be driven by increasing need to reduce design time, need for visualization for more efficient PCB design, and focus on reducing PCB production costs. This option should be checked by default.The global Printed Circuit Board (PCB) design software market size reached USD 1.15 Billion in 2020 and is expected to register a revenue CAGR of 6.9% during the forecast period. To ensure that your design stays within fab specs, make sure that this option is checked before running your DRC. If this option is left unchecked, it’s possible for the copper pour to violate the DRC settings, and DipTrace won’t throw any errors.

Copper Pours Conflictĭiptrace has a Check Copper Pours option that will determine whether the copper plane is checked for copper spacing violations. We have a page for Ensuring Plated Holes with screenshots and instructions. Unfortunately, DipTrace has a Pad/Via Holes option that can cause all the holes to be unplated.

Copper under a drill means via/plated hole no copper means an unplated hole. Ensuring Plated HolesĪlso, our fabs use the presence of copper under or above a drill hole to determine whether or not a drill will be plated. Idyl.io has written an excellent DipTrace tutorial (pdf) that covers exactly how to set up your design rules before starting your design, and then how to generate gerbers when you’re ready to submit a design to us. DipTrace is a free downloadable PCB design tool.

0 kommentar(er)

0 kommentar(er)